A Distribution Transformer is an essential component in electrical power distribution systems, stepping down high voltage to lower voltage levels suitable for end-user applications. These transformers are designed for efficiency, durability, and safe operation, ensuring a reliable power supply across industrial, commercial, and residential sectors.

Design Types

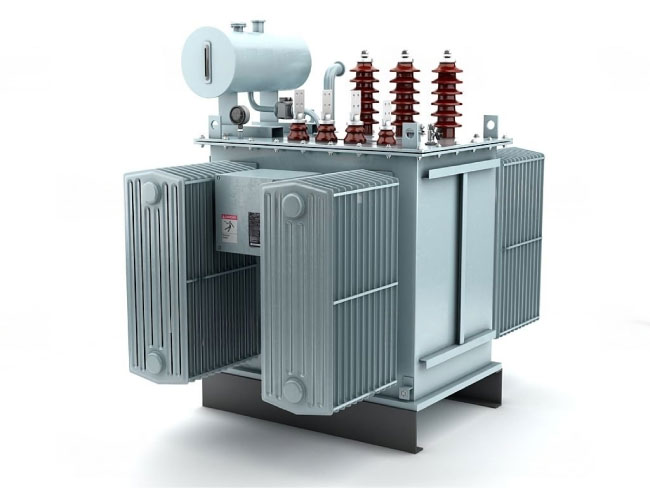

Oil-Filled Distribution Transformers:

- Suitable for outdoor and high-load applications.

- Offers high durability and better cooling efficiency.

Dry-Type Distribution Transformers:

- Ideal for indoor applications where fire safety is critical.

- Requires minimal maintenance.

Customization Options

We offer customization to meet specific needs:

- Voltage Levels: Primary and secondary voltages can be tailored.

- Cooling Options: Natural or forced air/oil cooling based on environment.

- Mounting Styles: Pole-mounted, pad-mounted, or indoor units.

- Accessories: Surge arresters, on-load tap changers (OLTC), off-circuit tap changers (OCTC), and monitoring systems.

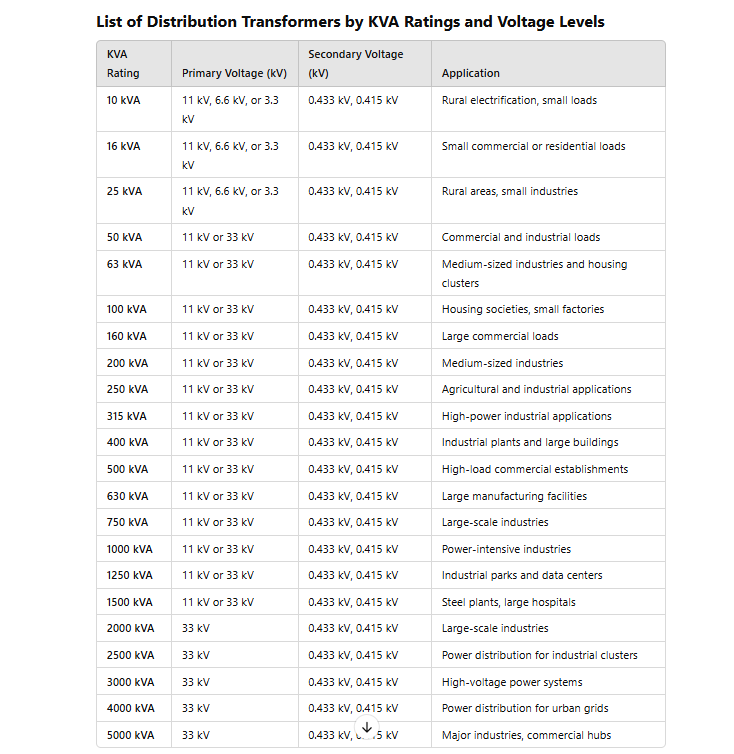

Common Voltage Combinations for Distribution Transformers

Primary Voltage:

- 11 kV (Common for urban and rural power distribution)

- 22 kV (For medium-voltage networks)

- 33 kV (High-voltage power networks)

Secondary Voltage:

- 0.433 kV or 0.415 kV (Common for residential and industrial usage)

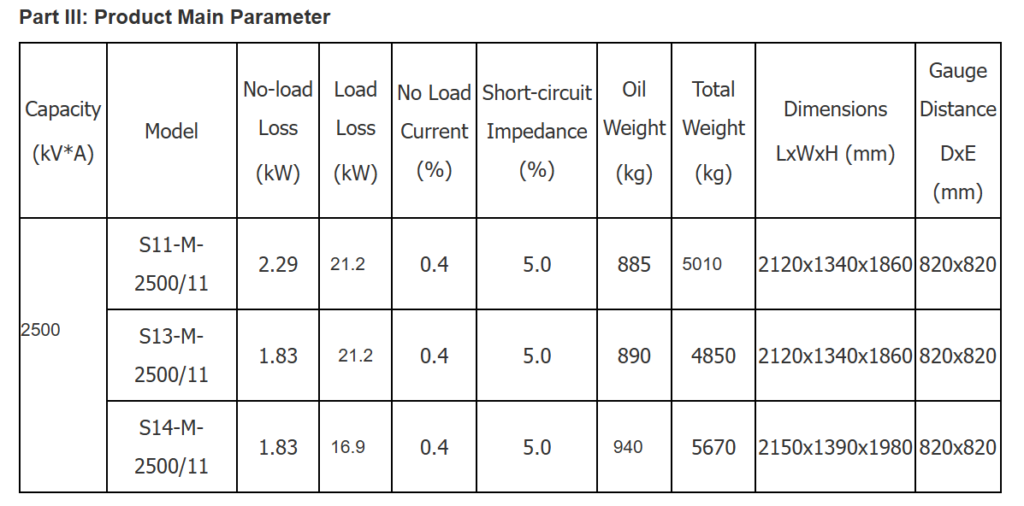

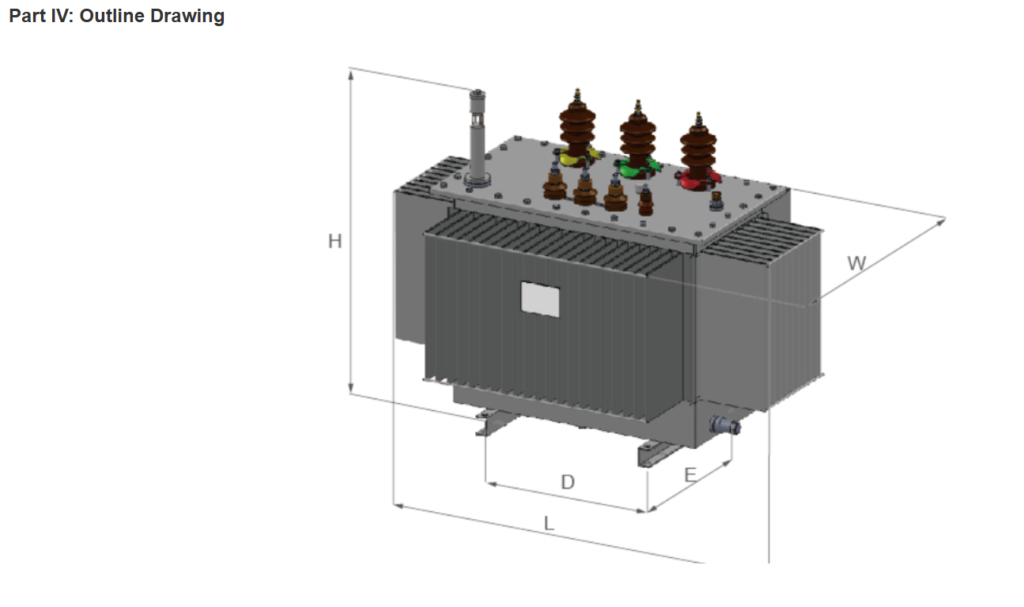

Part I: Product Overview for 2500kVA, 11Kv Transformer

2500kVA, 11kV Oil Immersed Distribution Transformer is usually pole mounted or installed in distribution station for daily lighting and factory power whose LV output up to 0.4kV. Hermetically sealed distribution transformer manufactured by us are with corrugated radiators. The corrugated tank as a thermal expansion and contraction components enable the transformer oil completely isolated with the atmosphere. Distribution transformer can be manufactured according to the requirement of client.

Part II: Product Features

1. Distribution transformer is optimally designed by patented technology and software. Its performance parameters and requirements meet IEC Standards and Chinese National Standards and so on.

2. The core is made of high quality cold -rolled grain-oriented silicon steel sheet which produced in step-lap technology by automatic core lamination line from GEORG Germany.

3. The oil tank is corrugated type and fabricated by Germany GEORG ultra-corrugation tank wall production lines. Tank surface pre-treatment liquid and coating powder adopts international top brands. The tank is degreasing, pickling phosphorated electrophoresis by automatic GEORG production lines then power spray coating and heat-solidify. The tank of transformer is highly corrosion resistance.

4. The HV winding of distribution transformer is made of high strength enamelled wire or paper-insulated wire the LV winding is made of high strength enamelled wire on paper-insulated wire and copper belt winding, which offers uniform distribution of ampere turns, reasonable insulation structure so as to offer high ability to withstand short-circuit.

5. The active part applies core free-hanging structure. The gasket is made of high quality acrylate rubber which can inhibit ageing caused by sun and heat.