33kV Power Transformer

Part I: Product Overview for 2500kVA 33kV Power Transformer

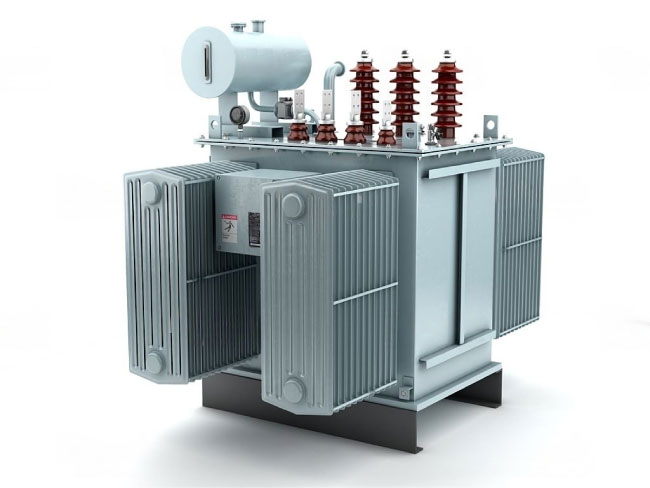

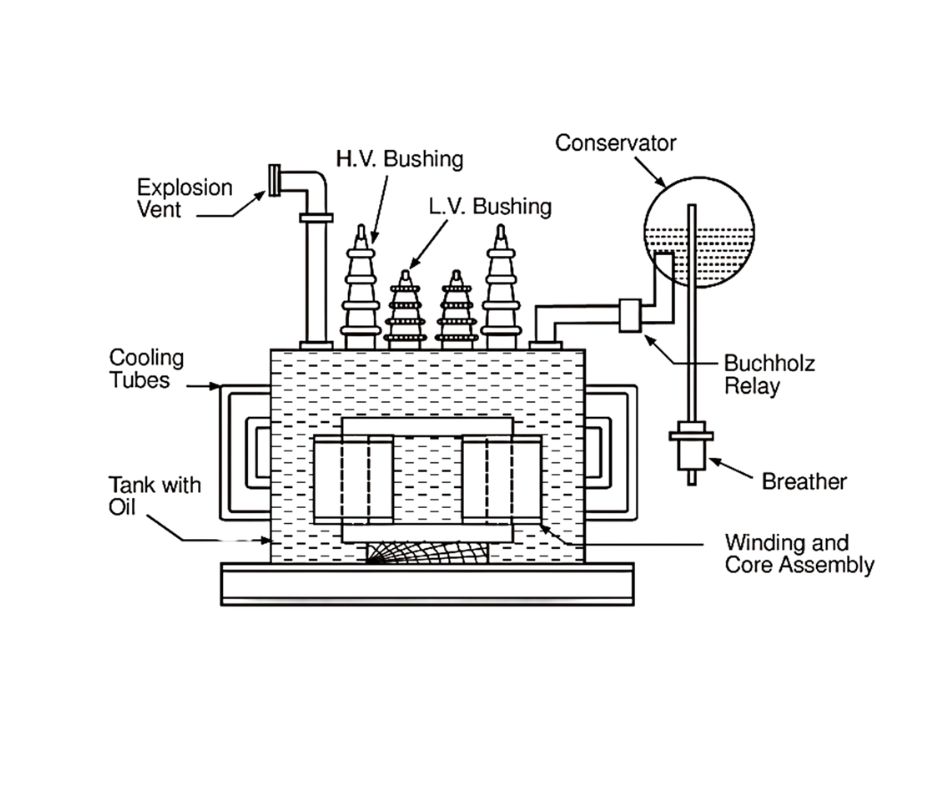

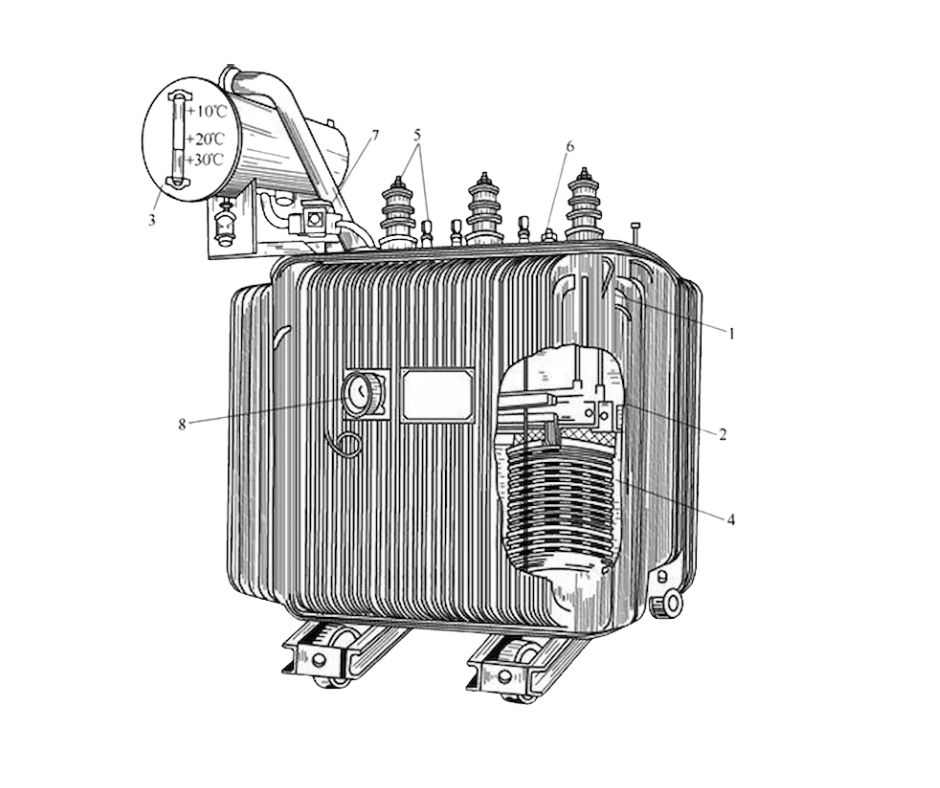

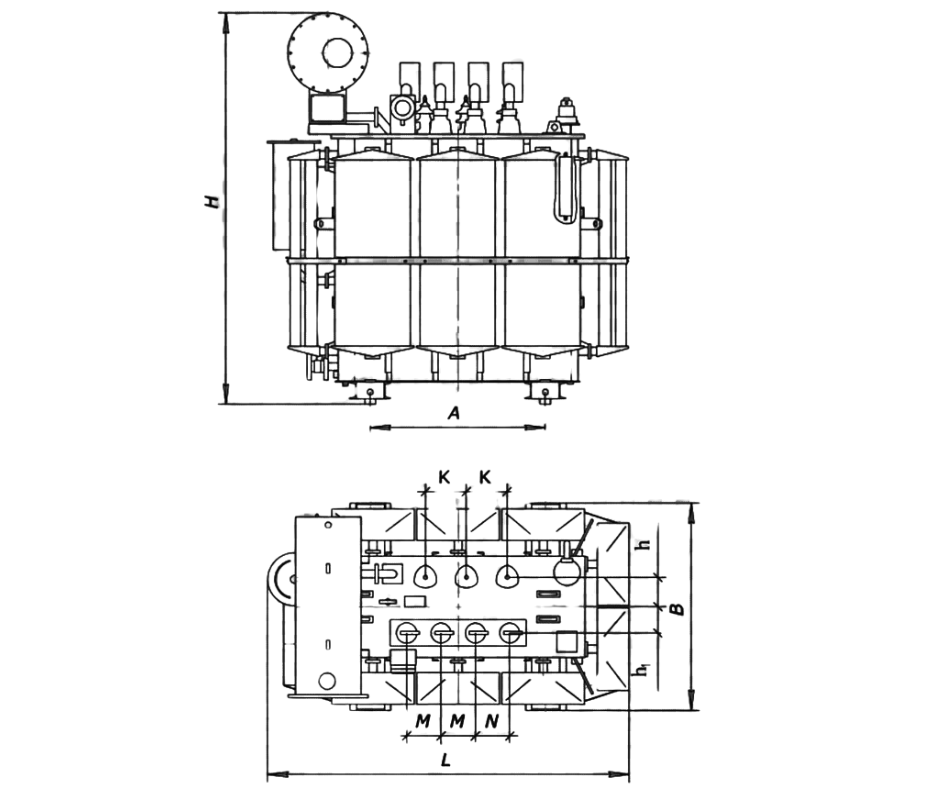

2500kVA 33kV high quality oil immersed Power Transformer has optimized design using advanced technologies, in order to offer low noise, low partial discharge, high short circuit withstand capability. Advanced design software are used for electromagnetic calculation and design of transformer, while 3-D, 2-D CAD software for structural design ensure sufficient safety margin during short circuit period. This is based on in-depth theoretical and experimental studies on magnetic, thermal, mechanical strength and short circuit strength. To ensure reliability of the transformer, the insulation is decided based on calculation on main and vertical insulation. The accurate calculation of the electric field distribution in inner coils will ensure voltage gradient and at coil end it will ensure lower partial discharge.

Part II: Product Features

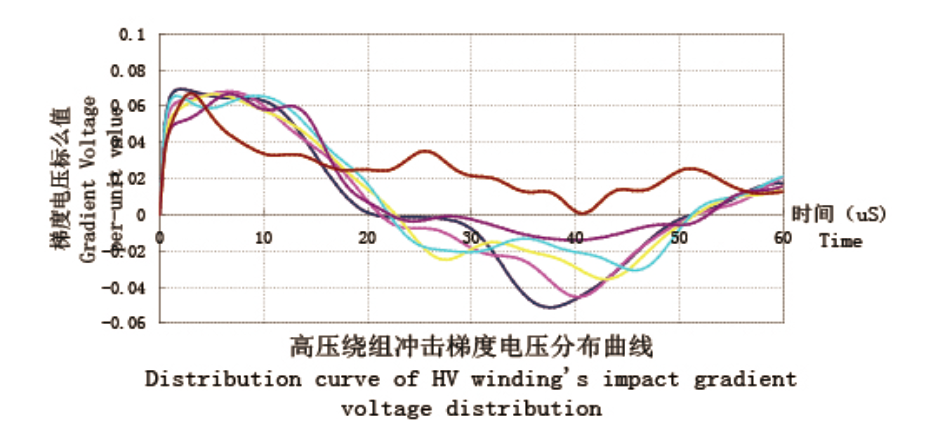

1. Potential distribution is effectively improved by application of software to calculate the impact and gradient potential distribution. The potential calculation is also done between various parts of the coil including between the coil and coil and earthing.

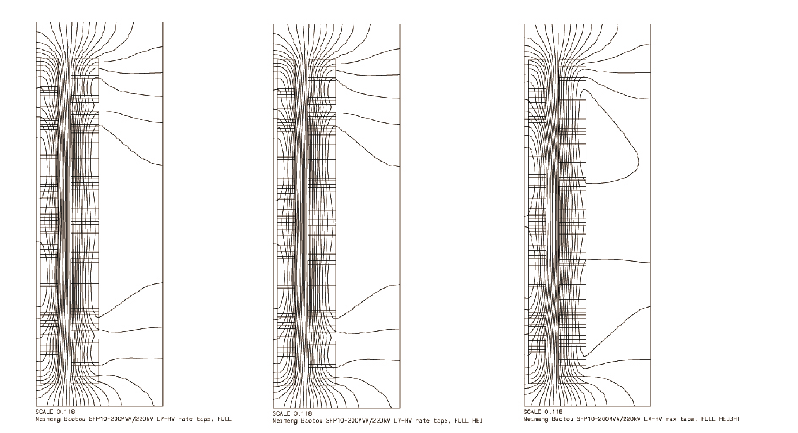

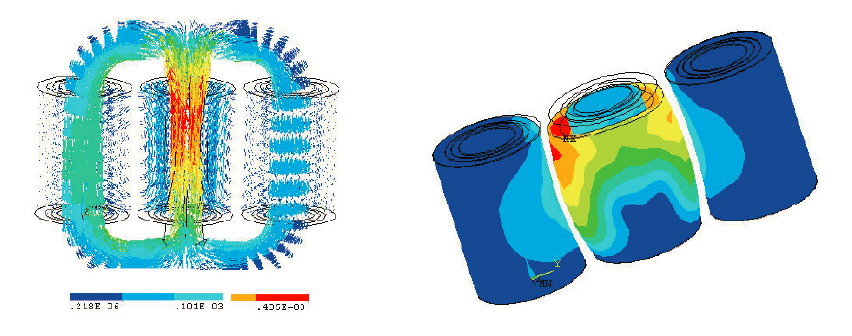

2. Low loss: Magnetic flux leakage calculation and corresponding measures to effectively reduce the stray loss, and in the meantime effectively prevent local overheating and lower temperature rise of winding hot spots. The electromagnetic optimizing design software is applied to optimize the core and winding design.

3. High resistance to short-circuit capacity: Apply transformer resistance to short-circuit capacity accounting software to design HV winding and LV winding. HV winding will be designed as central outlet, up and down parallel connection with axial oil path; the regulating winding will be designed as central outlet in the middle of HV winding with up and down parallel connection to improve transformer short-circuit resistance.

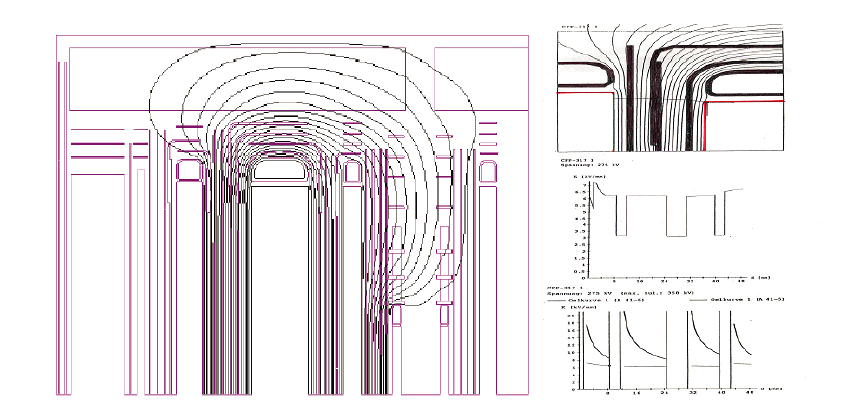

4. Low partial discharge, extend Transformer Service life.

(1) Analyze calculation of electric field to improve the electric field concentrated region.

(2) The way of vacuum oil filling will effectively prevent the formation of air bubbles inside the transformer and insulation parts to reduce partial discharge.

5. Low noise: Lower the noise level by choosing high quality steel core material; right flux density and the self-vibration frequency of the core; application of high resistance to short-circuit of the body structure; and improving the connection method of tank and active part.

6. Low temperature rise: Apply reasonable oil flow distribution structure by calculation of oil flow distribution; reduce the winding hot spot temperature rise and the average temperature rise in order to increase overload capacity of each part, extend the life of transformer.

Transformer

ATS POWER LTD. is prepared with all necessary manufacturing testing, installations and service facilities of power & distribution transformer according to IP-55 & IP-56. We are constantly monitoring quality, reliability & service of our products. Our product satisfies requirement of the Bangladesh Power Development Board (BPDB), Bangladesh Rural Electrification Board (BREB) Dhaka Power Distribution Company (DPDC), Dhaka Electric Supply Company (DESCO), Northern Electric Supply Company (NESCO) & West Zone Power Distribution Company (WZPDCO).

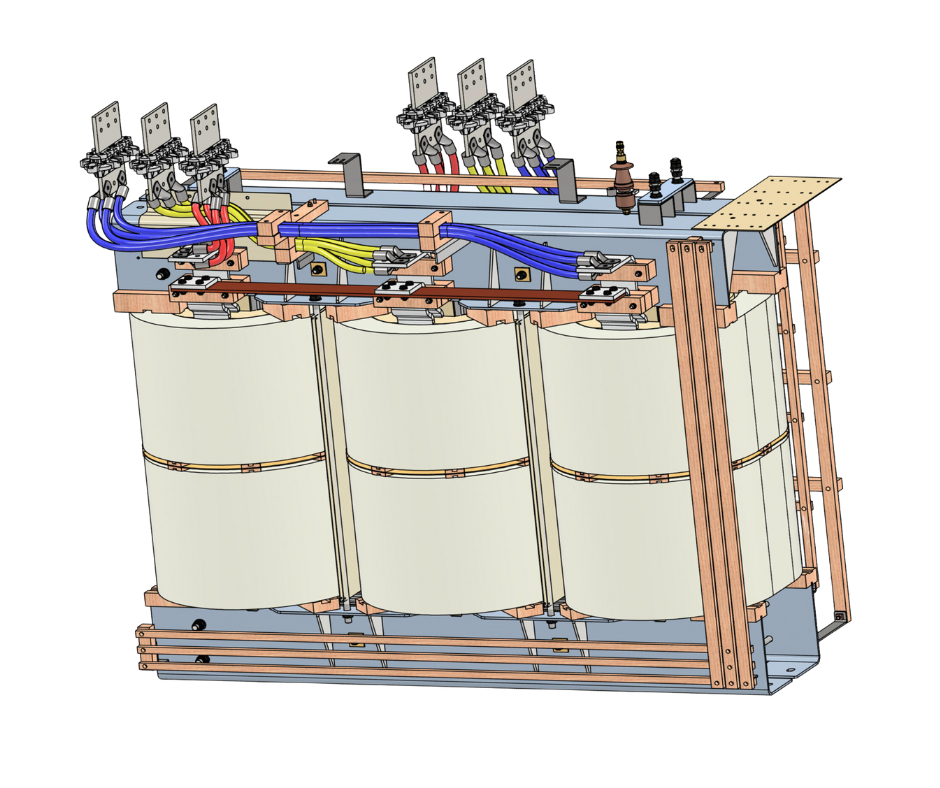

Windings

Windings of high voltage and low voltage are made of high conductivity electrolytic copper, other paper insulated pinhole free enamel wire. Ducts are provided both in the High Voltage & Low Voltage windings for all oil to circulate freely to keep the transformer sufficiently cool. Our every transformer is designed to meet the Basic Insulation Level (BIL) requirements fulfill all the short circuit requirements.

Product description

Amorphous core distribution transformers. Core is its amorphous alloy with soft magnetic material’s characteristics can further reduce the distribution system for loss and reduce air pollution. This new transformer transformer compared with the conventional silicon steel, cut 80% of the no-load loss is efficient and energy saving effect. Superscript reached the world’s advanced level. Amorphous alloy is a new energy-saving materials, iron, boron and other elements of solid materials used in producing rapid condensation urgent Arts, to their physical properties and performance of non-crystal metal atoms arranged disorderly, it is totally different from the crystal structure with silicon steel was more conducive to magnetization and magnetic. This new materials for transformer cores. Operating pressure changes at 100-120 times per second magnetized by the magnetic and said to be relatively easy thus greatly reducing the core of the no-load loss, but also reduce emissions if used in oil-immersed transformers CO, SO.NOX and other harmful gases, and has been called the 20th century’s “green materials.” SBH15-based amorphous alloy core distribution transformer products that both single or three-phase five-volume box cores. Core Molding frame clamping plates, foil around for the type of low voltage windings so low loss, the short circuit capacity. advanced structural reasonable overall performance indicators have reached the world’s advanced level.

Benefits

ATS Power Ltd. transformers offer significant energy efficiency by utilizing advanced amorphous alloy cores, which reduce no-load losses by up to 80%, leading to lower operational costs and reduced environmental impact. The high-quality copper windings and pinhole-free enamel wire ensure reliable, long-lasting performance, while optimized cooling through oil circulation maintains temperature stability. Compliant with IP-55 and IP-56 standards, these transformers meet the stringent requirements of major power distribution companies in Bangladesh. Their green materials contribute to lower emissions, and their durable design ensures resilience against short circuits, providing a reliable, eco-friendly solution for modern power distribution systems.

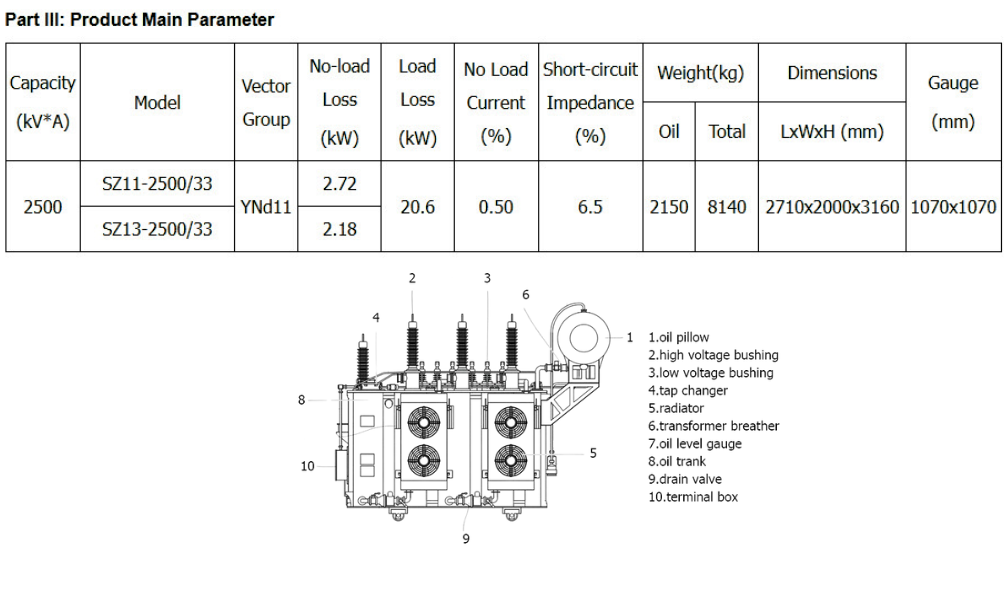

Technical Data

ATS Power Ltd. transformers are built with amorphous alloy cores that reduce no-load losses by up to 80% compared to conventional designs. They feature high conductivity electrolytic copper windings and pinhole-free enamel wire insulation for enhanced durability and performance. These transformers are designed to meet IP-55 and IP-56 protection standards, ensuring resistance to dust and water. They are available in single-phase and three-phase configurations, with options for five-volume box cores. The cooling system is optimized with ducts for efficient oil circulation, maintaining optimal temperature levels. Designed to meet Basic Insulation Level (BIL) and short circuit requirements, they are reliable and energy-efficient solutions for modern power distribution.